PoliCarb®

Gallina has been manufacturing and extruding polycarbonate and plastic profiles, sheets and building panels for over 50 years. Our Policarb® line of structural multiwall polycarbonate sheets are the highest quality available on the market today. We offer a variety of widths, lengths, thicknesses, profile structures, colors and glazing options to satisfy all of your building and industrial needs. Call us to discuss what panel is right for your job.

Multiwall U.V. protected polycarbonate sheets

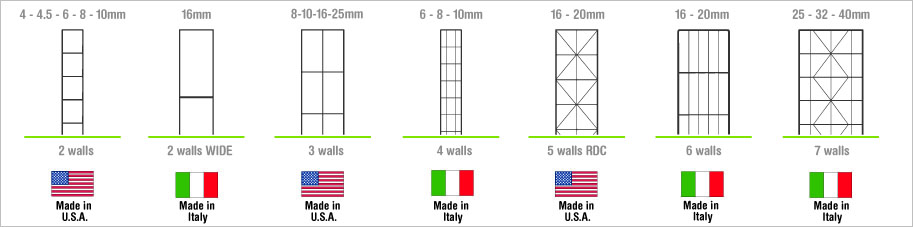

| Thickness (mm) | 4 | 4.5 | 6 | 8 | 10 | 8 | 10 | 16 | 20 | 25 | 6 | 8 | 10 | 16 RDC | 20 RDC | 25 | 32 | 40 |

| Thickness (in) | 5/32 | 3/16 | 1/4 | 5/16 | 3/8 | 5/16 | 3/8 | 5/8 | 3/4 | 1 | 1/4 | 5/16 | 3/8 | 5/8 | 3/4 | 1 | 1-1/4 | 1.57 |

| Structure | 2 LAYERS | 3 LAYERS | 4 LAYERS | 5 LAYERS | 7 LAYER | |||||||||||||

| Consult GallinaUSA for availability | ||||||||||||||||||

| Width (in) | 47.25″, 48″, 71.25″, 72″ plus custom widths available upon request. | 49-1/4 | ||||||||||||||||

| Length (ft) | Made in the USA products limited only by transportation constraints | |||||||||||||||||

| Weight (lbs/sf) | 0.164 | 0.205 | 0.266 | 0.307 | 0.348 | 0.348 | 0.430 | 0.553 | 0.650 | 0.665 | 0.286 | 0.317 | 0.358 | 0.522 | 0.635 | 0.655 | 0.716 | 0.799 |

| R-Factor | 1.471 | 1.471 | 1.639 | 1.724 | 1.923 | 1.923 | 2.128 | 2.500 | 2.632 | 2.941 | 1.887 | 2.083 | 2.273 | 2.778 | 3.030 | 3.846 | 4.167 | |

| U-Value | 0.680 | 0.680 | 0.610 | 0.580 | 0.520 | 0.520 | 0.470 | 0.400 | 0.380 | 0.340 | 0.530 | 0.480 | 0.440 | 0.360 | 0.330 | 0.260 | 0.240 | |

| Light Transmission % | ||||||||||||||||||

| Clear | 85 | 84 | 80 | 81 | 82 | 76 | 74 | 74 | 75 | 72 | 79 | 79 | 79 | 65 | 65 | 63 | 62 | 55 |

| Bronze | 57 | 57 | 42 | 42 | 42 | 42 | 37 | 35 | 35 | 30 | 30 | 35 | 35 | |||||

| Opal | 58 | 58 | 57 | 57 | 57 | 52 | 52 | 52 | 35 | 50 | 50 | 50 | 40 | 40 | 42 | 42 | 40 | |

| Reflecto | 48 | 48 | 38 | 35 | 37 | 35 | ||||||||||||

| Blue | 53 | 53 | 48 | 45 | ||||||||||||||

| Green | 54 | 54 | 54 | 42 | ||||||||||||||

| Solar Heat Gain Coefficient | ||||||||||||||||||

| Clear | 83 | 82 | 80 | 82 | 82 | 78 | 75 | 75 | 77 | 78 | 81 | 81 | 72 | 68 | 68 | 61 | 60 | 61 |

| Bronze | 66 | 66 | 66 | 70 | 75 | 57 | 57 | 57 | 51 | 50 | 50 | 50 | 50 | |||||

| Opal | 66 | 66 | 66 | 65 | 64 | 62 | 63 | 63 | 51 | 51 | 51 | 45 | 45 | 50 | 54 | 50 | ||

| Reflecto | 45 | 43 | ||||||||||||||||

| Blue | 66 | 70 | 70 | 65 | ||||||||||||||

| Green | 66 | 70 | 70 | 60 | ||||||||||||||

| Shading Coefficient | ||||||||||||||||||

| Clear | 0.95 | 0.94 | 0.91 | 0.94 | 0.94 | 0.90 | 0.86 | 0.86 | 0 .88 | 0.75 | 0.93 | 0.93 | 0.78 | 0.78 | 0.78 | 0.70 | 0.69 | .70 |

| Bronze | 0.76 | 0.76 | 0.76 | 0.8 | 0.86 | 0.65 | 0.65 | 0 .65 | 0.58 | 0.57 | 0.57 | 0.57 | 0.57 | |||||

| Opal | 0.76 | 0.76 | 0.76 | 0.75 | 0.74 | 0.71 | 0.72 | 0.72 | 0.59 | 0.58 | 0.58 | 0.52 | 0.52 | 0.57 | 0.52 | .57 | ||

| Reflecto | 0.52 | 0.52 | 0.59 | 0.49 | ||||||||||||||

| Blue | 0.76 | 0.80 | 0.80 | 0.74 | ||||||||||||||

| Green | 0.76 | 0.80 | 0.80 | 0.69 | ||||||||||||||

| Thermal ExpansionAllow 1/8″ per 3′ per 100° temp differ. for both length and width for clear and opal. 1/4″ per 4′ for bronze | ||||||||||||||||||

| Fire Reaction | Class A 6, 8, 10, 16mm Other thicknesses Class A (ASTM E-84) upon request. Additional test results supplied upon request | |||||||||||||||||

Advantages:

❖ Light transmission

❖ Resistance to U.V. rays and to hail

❖ Energy saving

❖ Economical

❖ Versatile

Applications

❖ Vertical windows

❖ Roofing

❖ Curved roofing

❖ Ceiling

FIXED PLANE SHEETS ON 4 SIDES

*contact Gallina for specific testing where available

Cold Bended Sheets

In particular Policarb® is used to build integral arc structures (green house tunnel type) since its alveolar structure increases the rigidity of the sheet longitudinally bent at its ribs.

It is recommended not to go under the bending radius of load charts.

| Sheet thickness (mm) | 4.5 | 6 | 8 | 8-4P | 10 | 10-3w | 10-4w | 16 | 16 RDC | 20 | 20 RDC | 25 | 32 |

| Minimum radium (in) | 30 | 39 | 55 | 63 | 69 | 79 | 79 | 110 | 138 | 138 | 157 | DO NOT BEND | |

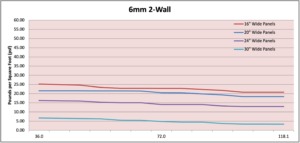

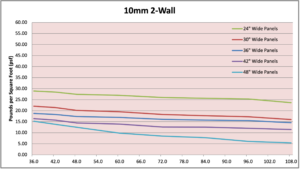

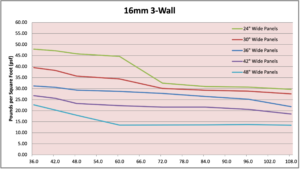

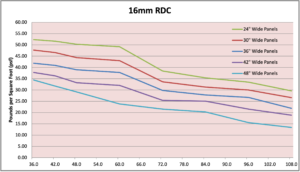

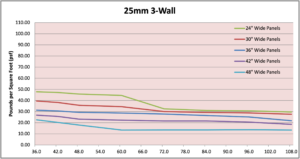

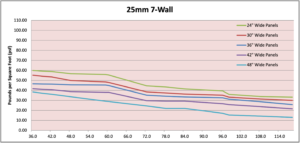

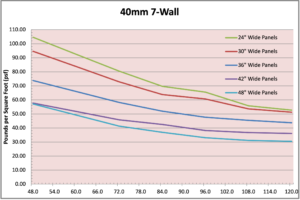

LOADING CAPACITY (psf )

FIXED SHEETS, COLD BENDED ON 4 SIDES

The chart shows max width of sheets in relation to thickness, with the bending radius and with the requested load.

To carry out the bending in an easier way, the length of the sheet has to be bigger than the width.

| Radius | 6 | 8 | 10 | 16 | 16RDC | 6 | 8 | 10 | 16 | 16RDC | 6 | 8 | 10 | 16 | 16RDC | 6 | 8 | 10 | 16 | 16RDC | |

| (ft) | (in.) | Width of Sheet (m) | |||||||||||||||||||

| 4.0 | 48 | 4.83 | 4.01 | 3.23 | 2.90 | ||||||||||||||||

| 4.5 | 54 | 4.08 | 3.28 | 2.80 | 2.45 | ||||||||||||||||

| 5.0 | 60 | 3.53 | 5.72 | 2.86 | 4.70 | 2.42 | 3.78 | 2.13 | 3.24 | ||||||||||||

| 5.5 | 66 | 3.03 | 4.89 | 2.46 | 3.83 | 2.11 | 3.20 | 2.78 | |||||||||||||

| 6.0 | 72 | 2.60 | 3.99 | 5.47 | 2.08 | 3.24 | 4.48 | 1.89 | 2.72 | 3.82 | 2.37 | 3.30 | |||||||||

| 6.5 | 78 | 2.46 | 3.77 | 5.25 | 1.97 | 3.02 | 4.20 | 1.80 | 2.56 | 3.54 | 2.23 | 3.05 | |||||||||

| 7.0 | 84 | 2.28 | 3.38 | 4.68 | 2.79 | 3.83 | 2.38 | 3.25 | 2.80 | ||||||||||||

| 7.5 | 90 | 2.10 | 3.07 | 4.26 | 2.52 | 3.51 | 2.96 | 2.58 | |||||||||||||

| 8.0 | 96 | 2.81 | 3.93 | 3.22 | |||||||||||||||||

| 9.0 | 108 | 3.18 | |||||||||||||||||||

| 10.0 | 120 | 2.85 | 5.71 | 4.65 | 3.89 | 3.41 | |||||||||||||||

| 11.0 | 132 | 2.52 | 4.96 | 4.13 | 3.54 | 3.13 | |||||||||||||||

| 12.0 | 144 | 4.50 | 5.15 | 3.89 | 4.05 | 3.37 | 3.74 | 3.00 | 3.28 | ||||||||||||

| 13.0 | 156 | 4.00 | 4.60 | 3.64 | 3.80 | 3.49 | 3.20 | ||||||||||||||

| 14.0 | 168 | 3.85 | 4.35 | 3.58 | 3.26 | 3.12 | |||||||||||||||

| 15.0 | 180 | 3.97 | 3.45 | 3.22 | 3.06 | ||||||||||||||||

| Load | 16.72 psf | 20.9 psf | 25.08 psf | 29.26 psf | |||||||||||||||||

| Thickness (mm) | Length (in) |

cod. | Profile “H” U.V. protected |

| 4-6 | 288 | 1162/6000 |

|

| 8-10 | 288 | 1164/6000 | |

| 16 | 288 | 1165/6000 |

| Thickness (mm) | Length (in) |

cod. | Profile “U” U.V. protected |

| 4-6 | 288 |

1158/2100 |

|

| 8-10 | 288 |

1160/2100 |

|

| 16-20 | 288 |

1161/2100 – 2184/2100 |

|

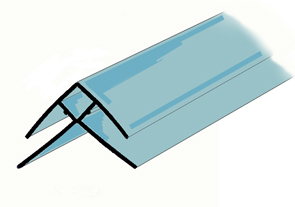

Profile “R” U.V. protected

|

Thickness (mm)

|

Length (in)

|

|

8 – 10 /16

|

236

|

|

cod. 2191/6000 – 2192/6000

|

||

|

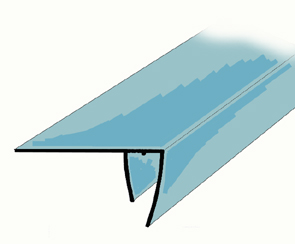

Profile “F” U.V. protected

|

Thickness (mm)

|

Length (in)

|

|

8 10/16

|

288

|

|

cod. 2193/6000 – 2194/6000

|

||

| Thickness (mm) | Length (in) | Profile “U” in AL |

| 10 / 16 | 288 |  |

| cod. 4285/6000 – 4286/6000 | ||

| Thickness (mm) | Length (in) | Profile Superior in AL |

| 2 – 10 | 288 |

|

| cod. 4272/6000/A | ||

| Thickness (mm) | Length (in) | Profile Superior in AL |

| 16 – 20 | 288 |

|

| cod. 4279/6000/A | ||

| Thickness (mm) | Length (in) | Profile Inferior in AL |

| 2 – 10 | 288 |

|

| cod. 4273/6000/A | ||

| Thickness (mm) | Length (in) | Profile Inferior in AL |

| 16 – 20 | 288 |

|

| cod. 4280/6000/A | ||

|

Washers with Gaskets: |

|---|---|

| sp. 4 -6 cod.4077 sp. 8 -10 cod.4076 sp. 16 cod.4087 |

Click on a product line and then a link within to open or right click the link to download.